the Sea-Gull ST2100 is an excellent choice and Hangzhou 6300 also very good. The Liaoning SL-3000 is reportly also very good. The 2824-clone that has been reported least satisfactory has been the Shanghai Z2.

Z2, the crown height is the same as the 2836, and .5 mm off on the 2824, so im not 100% sure this swap will work seing as hes using the 2824

The following are known Chinese manufactured clones of the ETA 2824. They have all been sold to 3rd party assemblers as well as used by the house-brands of their respective manufacturers. The Sea-Gull movements have also been used as ebauche for Swiss movements. Perhaps some of the others have too.

Sea-Gull ST21 series (e.g. ST2130)

Hangzhou 6-series (e.g. 6300)

Liaoning Peacock SL3000

Shanghai Z2

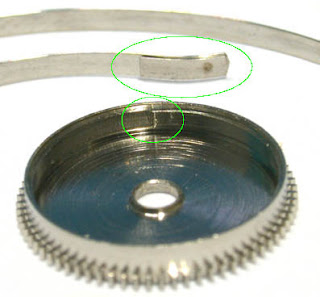

This shows the evolution from the eighties-era-designed Shanghai B to the recently-developed Z2. The movement in the middle is a kind of improved Shanghai B.The newly-developed Z2 is indeed a very good movement, on a par with his Seagull counterpart.